Further processing

Whether merging various components made from different materials, adding holes or forming entire workpieces, further processing takes many directions.

Forming holes (thermally/mechanically or using laser)

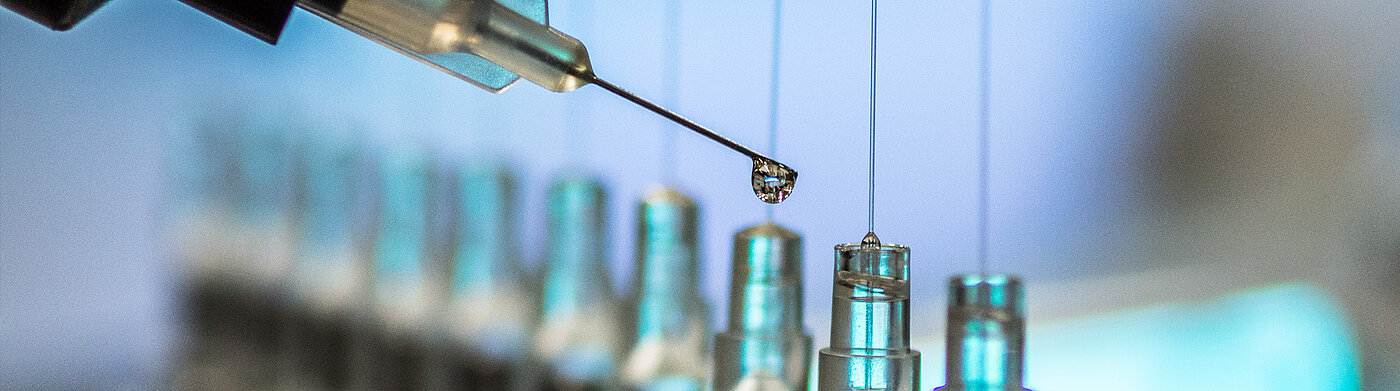

A very pointed and hot flame can be used to burn holes into the side wall of glass tubes and capillaries. The holes are often additionally blown out from the inside using compressed air. The edges of these holes are typically rounded.

Holes are mechanically drilled using a small diamond hollow drill, which grinds a hole into the surface of the glass. The area being processed is constantly dampened with a cooling and cutting fluid in order to achieve the best possible results with the drill. Once the tool has drilled through the glass and penetrated the reverse side of the glass, the core is ejected from the drill.

There are two types of laser drilling. First, there is thermal drilling, whereby a laser is used to heat the glass instead of a flame. The glass can either be only heated and then the hole blown out with air, or, alternatively, a focused laser beam vaporizes the glass. The type of laser drilling ultimately selected depends on the size of the hole and the type of glass.

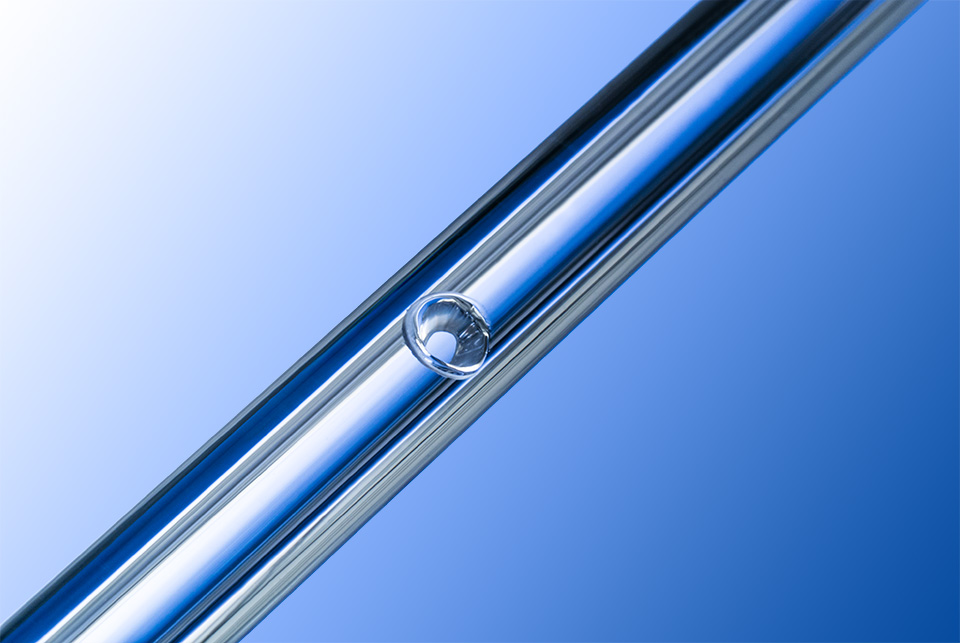

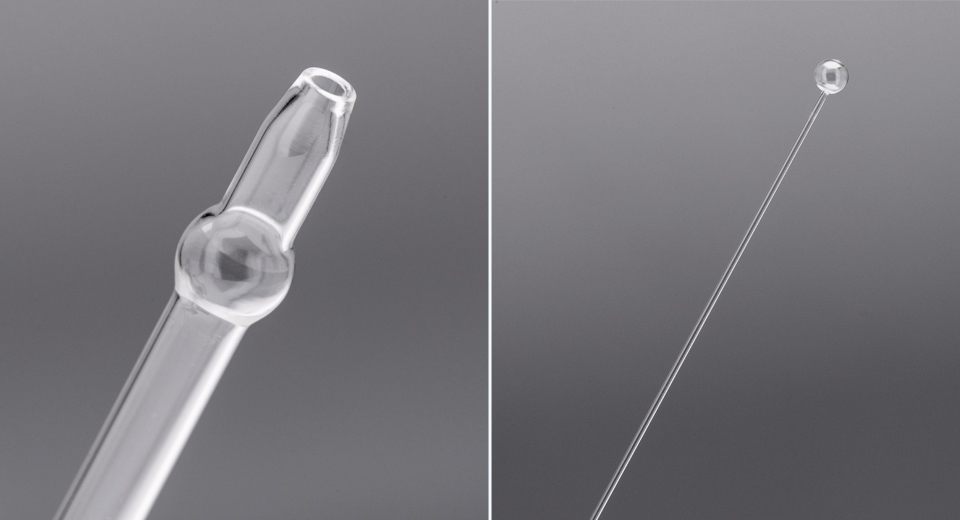

Blowing out bubbles at the end of or along tubes and capillaries

It is possible to form a bubble at the closed end of tubes and capillaries. To do this, the end of the glass is heated again and air blown into the tubes and capillaries until the preferred diameter has been achieved. A localized heating of the middle of the tubes is also possible, where the bubbles are then formed. Forming tools or molds can additionally be used from the outside to create longer bubbles, if preferred.

Thermal straightening of glass tubes and capillaries

The production process generally leaves glass tubes slightly bent and this usually won’t cause any issues, however it can be a problem for some applications, such as those in the fields of analytics or measurement technology. We are capable of thermally straightening tubes, rods, and capillaries. Parts are heated to an extent that only marginal deformation takes place and then straightened in rotation on a straightening bench. Depending on the material, component size and properties, straightness values of < 10 µm can be achieved.

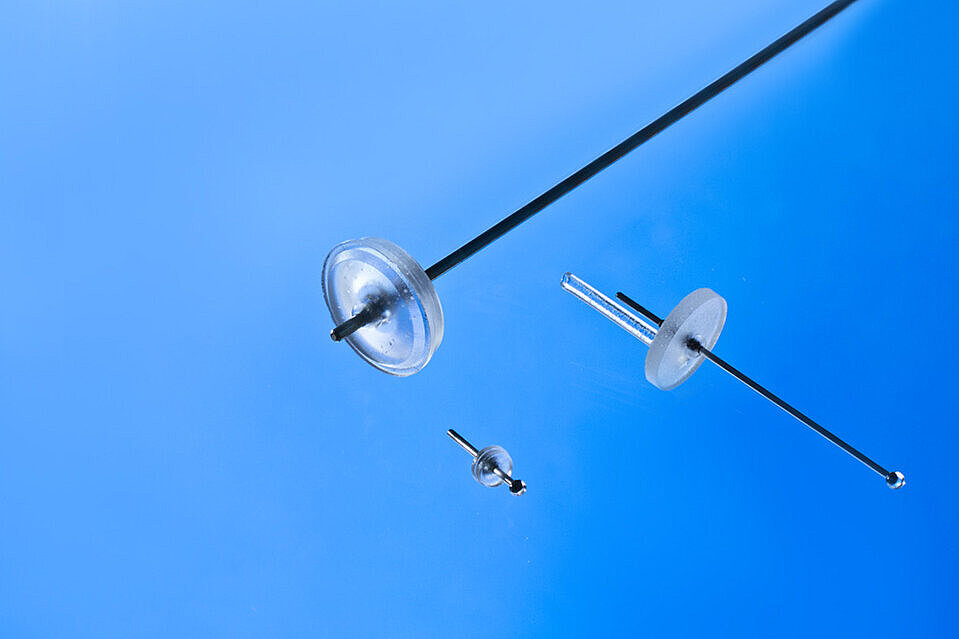

Tapering & Compression

There is a special type of thermal processing that does not involve the use of any tools, and the shape is solely changed through the targeted compression or drawing of the glass. For example, beads can be compressed or taperings and tips drawn.

Internal calibration on precision mandrels (KPG)

For the internal calibration of glass tubes, the glass tube is shrunk on a polished metal precision mandrel. A separator between the glass and mandrel prevents any adhesion of the surfaces. This process makes it possible to considerably increase the accuracy of glass tubes so that the smallest of tolerances for roundness and inside diameter can be maintained.

Bending of tubes and capillaries to max. 180°

Tubes and capillaries can be bent by up to 180°, allowing for the manufacture of pipes and pipe segments. Capillaries also often require angled ends so they can be used, for example, as nozzles in a combustion chamber or spectrometer.

Melting and joining of various components into one component

When both materials have approximately the same thermal expansion, under certain circumstances it is possible to melt glass directly with metals. For example, to bridge any gaps between metal and glass tubes, or when inserting wires into glass as electrical conductors, just like a light bulb.

Joining various glass materials together is also possible and facilitates, for example, the smooth transition between special glass made at high temperatures and glass with better properties for metal melting.

Adhesion of plastics with glass

Adhesion is a special way to join components made from glass. Through the use of special adhesive adapted specifically to glass (acrylates and epoxides), it is possible to create solid connections between not only glass and glass, but also glass and plastic or metals such as aluminum. The adhesion method offers great advantages when it comes to maintaining an accurate shape during joining or a low thermal load of the materials that are to be joined.

Thermal and chemical hardening and pretensioning of glass

Glass panes and tubes are often exposed to extreme stress. However, targeted hardening can considerably improve the material properties of the parts. The thermal pretensioning of glass panes, as well as larger tubes, will also guarantee greater breaking resistance. Chemical hardening is another option for several types of glass and involves the targeted replacement of molecules in the surface of the glass, making the glass mechanically stronger and less sensitive.